How to Lift More Crane Efficiently and Safely?

Lifting heavy loads with cranes is a critical task in construction and industry. To lift more crane efficiently and safely, understanding key principles is essential. Every lift poses challenges. Equipment must be in top condition. Operators need proper training.

Consider the load's weight and size. Misjudging these factors can lead to accidents. Cranes need to be set on stable ground. Unpredictable conditions can arise at any moment. Factors such as wind, weather, and proximity to obstacles must be constantly evaluated.

Communication is paramount. Teams should collaborate effectively to ensure safe lifting practices. Regular safety checks keep everyone updated. Reflecting on past experiences helps improve techniques. Remember, even minor oversights can have significant consequences. Enhancing safety and efficiency is an ongoing process.

Understanding the Basics of Crane Operation and Safety Standards

Crane operation is not just about lifting heavy loads. It is crucial to understand safety standards to prevent accidents. Always check the load capacity. Ignoring this can lead to catastrophic failures. Operators should be trained and certified. Proper training enhances skills and promotes safety.

Positioning the crane correctly is vital. An unstable base can cause tipping. Use outriggers and check ground conditions. Visibility matters. Ensure that all workers are visible during operations. Communication is key. Use hand signals or radios to maintain clear exchanges.

Regular maintenance is necessary for safety. Inspect hooks, cables, and brakes frequently. Small issues can escalate quickly if ignored. Always keep informed about updates in safety regulations. Following these can lead to safer and more efficient operations. However, complacency is a risk. Remember, safety should always come first.

Assessing Load Capacity and Choosing the Right Crane for the Job

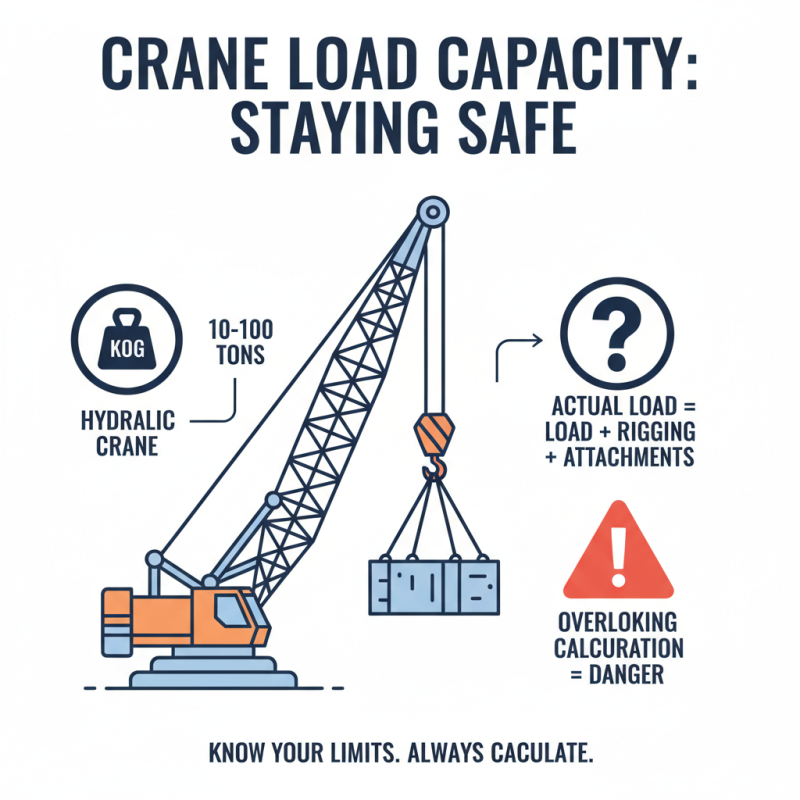

When lifting loads, understanding load capacity is vital. Each crane has a specific weight limit based on its design and strength. For example, a standard hydraulic crane can typically lift loads ranging from 10 to 100 tons. However, many operators overlook the importance of calculating actual load weights, including rigging and attachments. This can lead to dangerous situations.

Choosing the right crane for the job starts with accurate load assessment. A study by the International Association of Bridge, Structural, Ornamental and Reinforcing Iron Workers showed that nearly 40% of lifting accidents are due to improper load calculations. Additionally, factors such as load shape and lift height can affect stability. A load that is poorly balanced may tip, leading to catastrophic failures.

Many operators may underestimate environmental conditions. Wind speed, ground stability, and overhead obstacles all influence crane performance. Data from the Occupational Safety and Health Administration indicates that crane accidents increase by 20% in high-wind conditions. Therefore, it's crucial to assess both the load and the lifting environment before proceeding. Engaging in thorough preparation can make all the difference.

Implementing Effective Rigging Techniques for Enhanced Stability

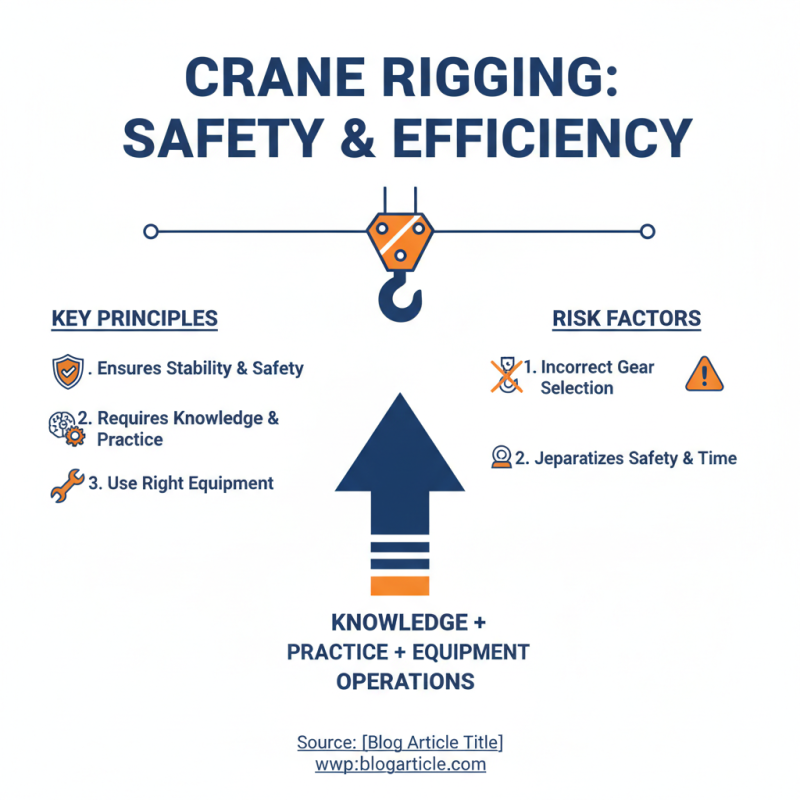

Effective rigging techniques are critical for safe and efficient crane operations. Proper rigging ensures stability. Achieving this requires knowledge and practice. Using the right equipment is key. Each job has unique requirements. Selecting the wrong rigging gear can lead to mistakes. This can jeopardize safety and increase project time.

Here are some tips to improve rigging techniques. Always inspect equipment before use. Look for signs of wear or damage. Ensure all components are rated for the load. Ensure everyone understands their roles during a lift. This clarity can prevent accidents and miscommunication. Use tag lines when necessary to control loads.

Reflection is essential in lifting operations. Review past lifts regularly for safety bottlenecks or issues. Document any problems encountered. Learning from experiences can enhance future performance. It is not just about lifting more but lifting safely. Prioritize stability and team communication for better results.

Recognizing and Mitigating Common Crane Hazards During Lifting

Crane operations involve various risks that can lead to accidents or injuries. According to the Bureau of Labor Statistics, nearly 50% of crane-related fatalities occur due to contact with power lines. Operators must always be aware of their surroundings. A thorough assessment of the lifting area is crucial to identify potential hazards.

Overloading is another common issue. A study by the National Institute for Occupational Safety and Health shows that improper load handling contributes to 36% of crane accidents. Operators should always verify the load weight before lifting. Using load indicators can help ensure safety. Regular inspections are vital. These ensure that safety features are functioning correctly.

Training is often overlooked but is essential. Many crane operators lack adequate training. This leads to poor decision-making during critical moments. Companies should invest in comprehensive training programs. Empowering operators with knowledge can significantly reduce risks. Regular safety drills can also enhance awareness and readiness. A culture of safety should be a priority.

Establishing a Routine for Crane Maintenance and Inspections

Regular maintenance and inspections are vital for crane safety and efficiency. Establishing a routine helps in identifying potential issues before they become serious. A well-planned schedule can keep your equipment in top shape. Inspections should focus on key areas like cables, hydraulic systems, and safety features. These checks should occur daily, weekly, and monthly depending on usage.

While performing inspections, it's easy to overlook minor details. Even a small crack can lead to bigger problems. Keeping a detailed log can enhance accountability and aid in tracking maintenance history. Training your team to recognize warning signs is essential. Sometimes, team members might miss signs of wear and tear. Encourage an open dialogue about safety concerns.

Creating a checklist will streamline the inspection process. This ensures that nothing is overlooked. Don’t just push through it; take time to analyze each component. Continuous reflection on maintenance practices fosters improvement. Safety should never be assumed. Always be proactive, and address any issues directly.

How to Lift More Crane Efficiently and Safely? - Establishing a Routine for Crane Maintenance and Inspections

| Inspection Type | Frequency | Responsible Person | Last Completed | Next Due |

|---|---|---|---|---|

| Visual Inspection | Daily | Operator | 2023-10-01 | 2023-10-02 |

| Operational Test | Weekly | Lead Technician | 2023-09-25 | 2023-10-02 |

| Load Test | Monthly | Safety Officer | 2023-09-20 | 2023-10-20 |

| Annual Inspection | Yearly | Inspection Agency | 2023-01-15 | 2024-01-15 |

Related Posts

-

What is a Lattice Boom Crane and How Does It Work in Construction

-

7 Best Lifting Cranes for Efficient Heavy Lifting in 2023

-

Top 10 Company Cranes to Watch in 2025: Trends and Innovations

-

How to Safely Use a Crane for Lifting and Rigging in Construction

-

What is a Truck Boom Crane and How Does it Work in Construction

-

What is the Largest Crane in the World and Its Incredible Capabilities