How to Safely Use a Crane for Lifting and Rigging in Construction

In the construction industry, the safe use of cranes for lifting and rigging is paramount to ensure both the efficiency of operations and the safety of personnel on site. Experts in the field, like John Smith, a leading professional in crane operations and safety, emphasize the importance of adhering to strict safety protocols. He once stated, “The key to effective crane operations lies in meticulous planning and execution, ensuring every lift is conducted safely and efficiently.”

Cranes, particularly the "crane lifting crane" types, play a critical role in handling heavy materials and equipment, but their misuse can lead to severe accidents. Proper training and understanding of load capacities, as well as the dynamics of the load, are essential for operators. With the right practices and knowledge, the construction workforce can minimize risks, ultimately enhancing workplace safety.

As the construction landscape evolves, embracing new technologies and safety guidelines becomes increasingly crucial. The sound application of lifting techniques not only protects lives but also supports the integrity of the project being executed. By prioritizing safe practices in crane operation, the industry can continue to thrive while safeguarding the well-being of its workers.

Understanding Crane Types and Their Uses in Construction

When it comes to construction, understanding the different types of cranes and their specific applications is crucial for ensuring safe and effective operations. Cranes can be broadly categorized into several types, each designed for unique lifting tasks. For instance, tower cranes are commonly used on large construction sites to lift heavy materials to significant heights, making them ideal for structures like skyscrapers. Meanwhile, mobile cranes offer versatility and the ability to maneuver in tight spaces, perfect for smaller projects where site conditions may vary.

Moreover, each crane type comes with its own set of features and operational guidelines. For example, crawler cranes, which have tracks instead of wheels, provide excellent stability on soft ground and are suitable for heavy lifting. On the other hand, overhead cranes, often found in warehouses and factories, allow for precision movement of loads across a defined area. Understanding these distinctions not only helps construction teams to select the appropriate crane for their project but also reinforces adherence to safety practices, minimizing the risk of accidents during lifting and rigging operations. By gauging the right equipment for specific tasks, professionals can enhance efficiency and ensure a safer working environment.

Crane Types and Their Usage in Construction

This bar chart illustrates the different types of cranes used in construction and their corresponding usage percentages. Understanding these categories can help ensure safety and efficiency in lifting and rigging activities.

Essential Safety Protocols for Crane Operation

When operating cranes in construction, adhering to essential safety protocols is paramount to ensure the well-being of all personnel involved. According to the Occupational Safety and Health Administration (OSHA), nearly 50% of crane-related accidents can be attributed to improper rigging, signaling, or inspection procedures. To mitigate these risks, it is crucial to establish a comprehensive safety management plan that encompasses thorough training for operators and riggers, as well as regular equipment inspections. Cranes must be inspected daily, and a certified professional should perform extensive checks according to the guidelines set forth by the American Society of Mechanical Engineers (ASME).

Additionally, maintaining clear communication among crew members is essential for safe crane operation. Implementing hand signals or two-way radio communication can significantly reduce the likelihood of misunderstandings during lifting operations. A study conducted by the Center for Construction Research and Training (CPWR) indicates that effective communication can decrease the rate of accidents by as much as 30%. Furthermore, ensuring that the worksite is adequately marked to keep unauthorized personnel at a safe distance can enhance safety. Awareness of environmental factors, such as wind speeds and ground conditions, is also critical, as adverse weather can lead to equipment destabilization and accidents. By focusing on these essential safety protocols, the construction industry can enhance its overall safety performance and protect the health of its workforce.

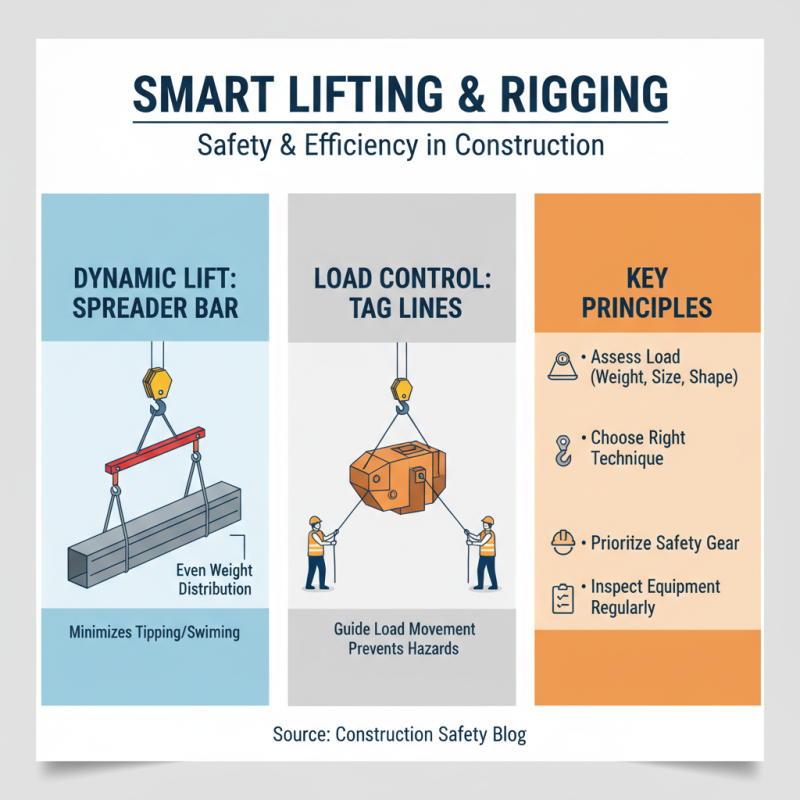

Lifting and Rigging Techniques for Various Loads

When it comes to lifting and rigging in construction, employing the right techniques is paramount to ensuring safety and efficiency. Different loads require specific lifting methods tailored to their weight, size, and shape. For instance, when lifting heavy machinery or large beams, a dynamic lift using a spreader bar is often recommended. This not only helps in distributing the weight evenly but also minimizes the risk of tipping or swinging during the lift. Additionally, the use of tag lines can control the load’s movement, keeping it stable and preventing potential hazards for workers below.

Furthermore, understanding the center of gravity for various loads is crucial in the rigging process. For irregularly shaped items, careful assessment is necessary to determine the most optimal rigging points to maintain balance during the lift. Techniques such as choker hitches and double-wrap hitches can be utilized to secure these loads, depending on their geometry and rigging configuration. Statics play a vital role here, as riggers must calculate forces accurately to avoid overloading the crane or rigging equipment. By employing these specialized techniques, construction teams can achieve safer and more effective lifting operations.

Inspection and Maintenance Practices for Cranes

Regular inspection and maintenance of cranes are critical to ensuring safety and efficiency in construction projects. Before any lifting operation, it is essential to conduct a thorough pre-operational inspection. This should include checking the overall condition of the crane, such as the integrity of the boom, cables, and rigging equipment. Operators should also inspect the crane’s control systems, brakes, and safety devices to confirm that everything functions correctly. Any signs of wear, corrosion, or damage should be addressed immediately, and defective components must be replaced to prevent accidents.

In addition to pre-use inspections, implementing a scheduled maintenance program is vital. This involves routine checks at set intervals to assess the crane’s performance and longevity. Maintenance tasks such as lubricating moving parts, adjusting mechanisms, and testing load limits can help in identifying potential issues before they escalate. Keeping accurate maintenance logs is also recommended, as they provide a historical account of the crane’s condition and repairs, which is crucial for regulatory compliance and operational safety. By following these inspection and maintenance practices, construction sites can mitigate risks associated with crane operations and ensure a safer working environment.

How to Safely Use a Crane for Lifting and Rigging in Construction - Inspection and Maintenance Practices for Cranes

| Inspection Item | Frequency | Maintenance Action | Responsible Party | Comments |

|---|---|---|---|---|

| Wire Rope Condition | Daily | Inspect for wear and fraying | Operator | Replace if damaged |

| Crane Brakes | Weekly | Test functionality | Maintenance Team | Adjust if necessary |

| Boom and Jib Inspection | Monthly | Check for cracks and corrosion | Safety Officer | Report any issues immediately |

| Hydraulic System | Quarterly | Inspect hoses and connections | Technician | Replace any worn hoses |

| Load Indicator Function | Before Each Use | Verify operation | Operator | Malfunction should be reported |

Training and Certification Requirements for Crane Operators

To safely operate a crane in construction, proper training and certification are essential for crane operators. These requirements not only enhance the operator’s skills but also ensure the safety of the entire construction site. Crane operators must typically undergo specific training programs that cover various aspects of crane operation, rigging techniques, load assessment, and safety procedures. Certification, often obtained through accredited organizations, verifies that the operator has met the necessary standards to operate different types of cranes safely.

Tips for aspiring crane operators include seeking out hands-on training experiences, as practical skills are just as vital as theoretical knowledge. Additionally, keeping up with safety regulations and industry best practices is crucial; regular workshops and refresher courses can help maintain and update these essential skills. Lastly, ensure that you understand the specific equipment you will be operating, as different cranes may have unique operational guidelines and safety features.

Investing time in comprehensive training not only prepares you to handle equipment efficiently but also significantly reduces the risk of accidents on site, making it a vital part of the construction process.

Related Posts

-

Top 10 Company Cranes to Watch in 2025: Trends and Innovations

-

7 Best Lifting Cranes for Efficient Heavy Lifting in 2023

-

The Best All Terrain Crane Models for Your Heavy Lifting Needs in 2023

-

What is a Boom Crane? Understanding Its Types, Uses, and Benefits

-

Exploring the Future: 2025's Largest Crane Innovations and Trends

-

Why You Should Choose a Robust Crane for Your Heavy Lifting Needs